Urgent Call?

+91-7453000063

Email Us

sales@acpvalves.in

+91-7453000063

sales@acpvalves.in

If you move liquids, you need non-return valves. They help keep the liquid moving in the right direction. For systems that move liquids, One way valve are very important. They help stop the liquid from moving and flowing too much. One of the most important types of valves you can buy is the NRV. This valve stops the medium from flowing the wrong way, which stops backflow that could hurt people, damage equipment, or mess up processes. Check valve are very important in pipelines for oil and gas, chemicals, and water. As demand grows, different Valves manufacturers in India and other countries make different types of One way valve and globe valve manufacturers to meet the needs of different industries. This page explains what a non return valve is, how it works, where it can be used and what makes the price of a return valve go up or down.

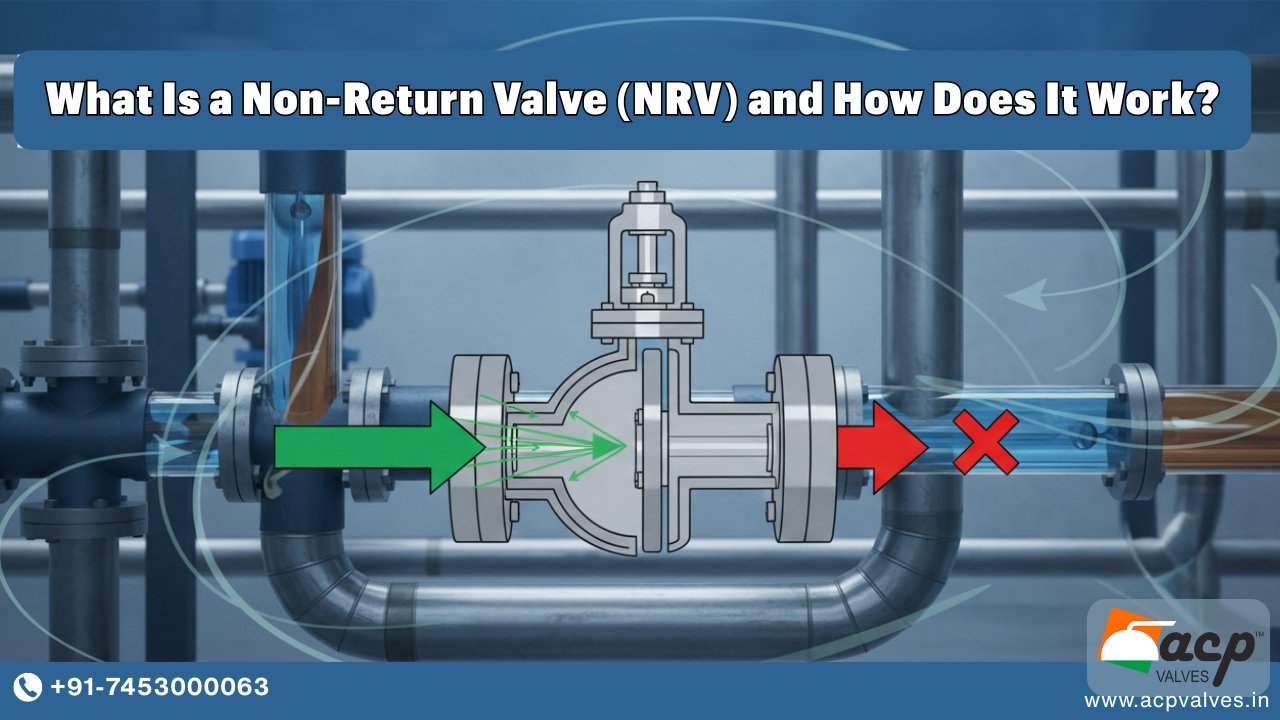

A non return valve is a safety valve that only lets liquid or gas flow in one direction. Its main job is to keep fluids from going back into a piping system. There is no need to manually or externally regulate an NRV; it works on its own based on the medium’s flow and pressure. A One way valve is like a door that only opens when the fluid is moving the right way. If the fluid tries to go back, the door closes right away.

It’s easy to understand how a non return valve works. When the fluid flows in the right direction with enough pressure, it pushes the valve mechanism, which could be a disk, ball, or flap. This force pushes against the resistance (spring or gravity), which opens the valve and lets the medium flow through. NRV is like a door that only opens when the fluid is moving the right way and closes straight away if the fluid tries to go back

The working principle of an NRV is simple yet effective:

So, NRVs are safety devices that turn on by themselves and make sure that things can only flow in one direction. This means that they don’t need any outside power or operator control.

Many kinds of Check valve can be used in homes and businesses.

There are different types of valves, and valve businesses in India develop solutions that are tailored to the demands of each sector.

Because they are so adaptable, non return valves can be employed in many different fields.

The material that makes up the non return valve determines its strength, lifespan, and cost.

The price of a One way valve can change based on many elements, including the

For example, non-return valve PVC is usually cheaper than heavy-duty stainless steel valves built for industrial use.

India is becoming a hub for high-quality industrial valves, including NRVs. There are a lot of well-known valve companies in India and throughout the world that make a lot of different types of valves for homes, farms, and businesses. A number of them also sell their goods all over the world because there is a lot of demand for affordable, dependable valves. Important people in the Indian market make sure that their One-way valve types meet all global criteria. This makes them valuable in a lot of fields, such as chemicals, oil and gas, water treatment, and power generation.

A non return valve is a simple but vital aspect of any system that moves fluids. The fundamental thing it does is let flow travel in one direction and stop it from moving the other way by itself. This preserves the equipment, keeps the process going, and makes sure the system is safe. You can choose from a lot of different One-way valve types. For example, PVC non return valves are good for residential usage, and stainless steel valves are good for heavy enterprises. Depending on the work, the media, and your budget, the right one for you will be different.The price of a check valve varies by type, but it’s crucial to get the appropriate one so it works well for a long time. Many well-known valve firms in India, like globe valve manufacturers and ball valve suppliers offer high-quality solutions for both the domestic and international markets as demand develops. If you choose the proper valve from a reputable valve maker in India, all of your systems will be safe, last a long time, and operate effectively.

The functioning of butterfly valves depends on application, it can actuated manually or automatically. Manually operated valves consisting of levers and gears suit simple and low pressure systems. Automatic butterfly valves offer fast, precise and remote control because of pneumatic or electric butterfly valve actuator solutions. This makes it ideal for complex industrial setups such as chemical plants, water treatment facilities and HVAC systems.

Copyright © 2022. All rights reserved.ACP VALVES